Electric cars, also known as EVs (electric vehicles), have recently gained significant traction in the automotive industry. These vehicles are powered by electric motors that utilize energy stored in rechargeable batteries.

Many drivers are attracted to the prospect of driving an electric car due to their numerous benefits, including lower fuel costs, reduced emissions, and a smoother driving experience.

With governments and automotive manufacturers around the world investing heavily in electric vehicle technology and infrastructure, it is important to understand the basics of how these vehicles operate and how they differ from their internal combustion engine counterparts.

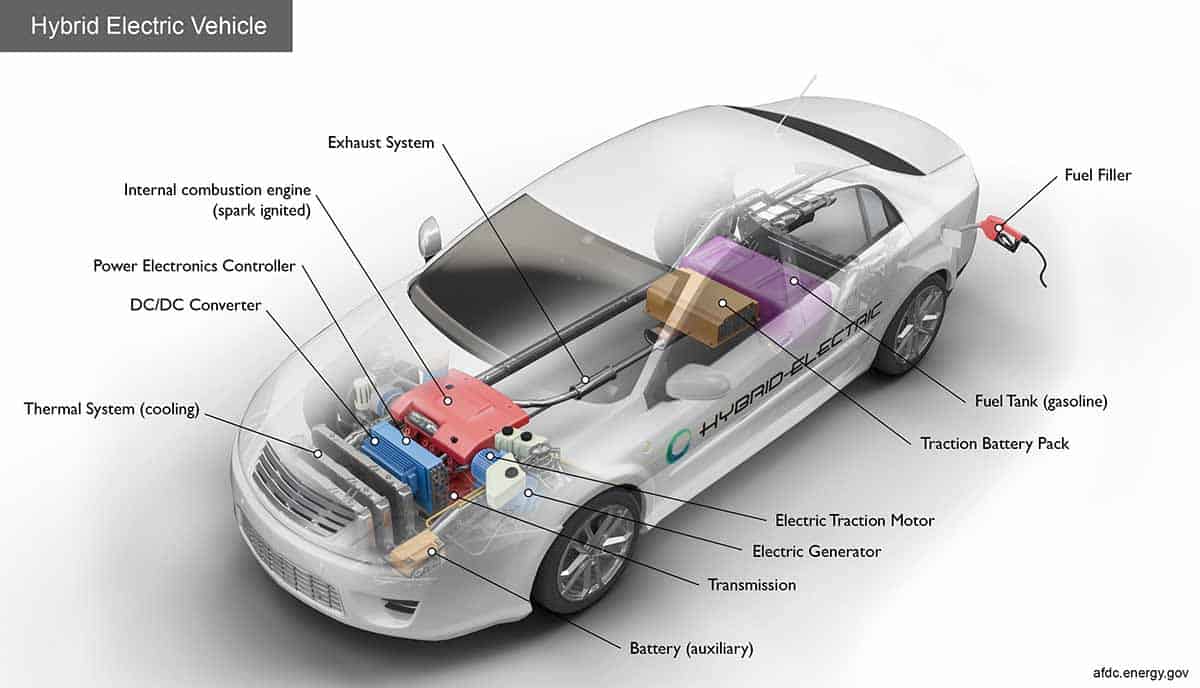

Technically speaking, not all EVs are fully electric, because hybrids also fall under the category of EV, being “Hybrid Electric Vehicles”.

But for the purposes of the following explanation, we will focus on fully electric EVs, i.e. those that only use electricity for power, and whose energy source is a rechargeable battery.

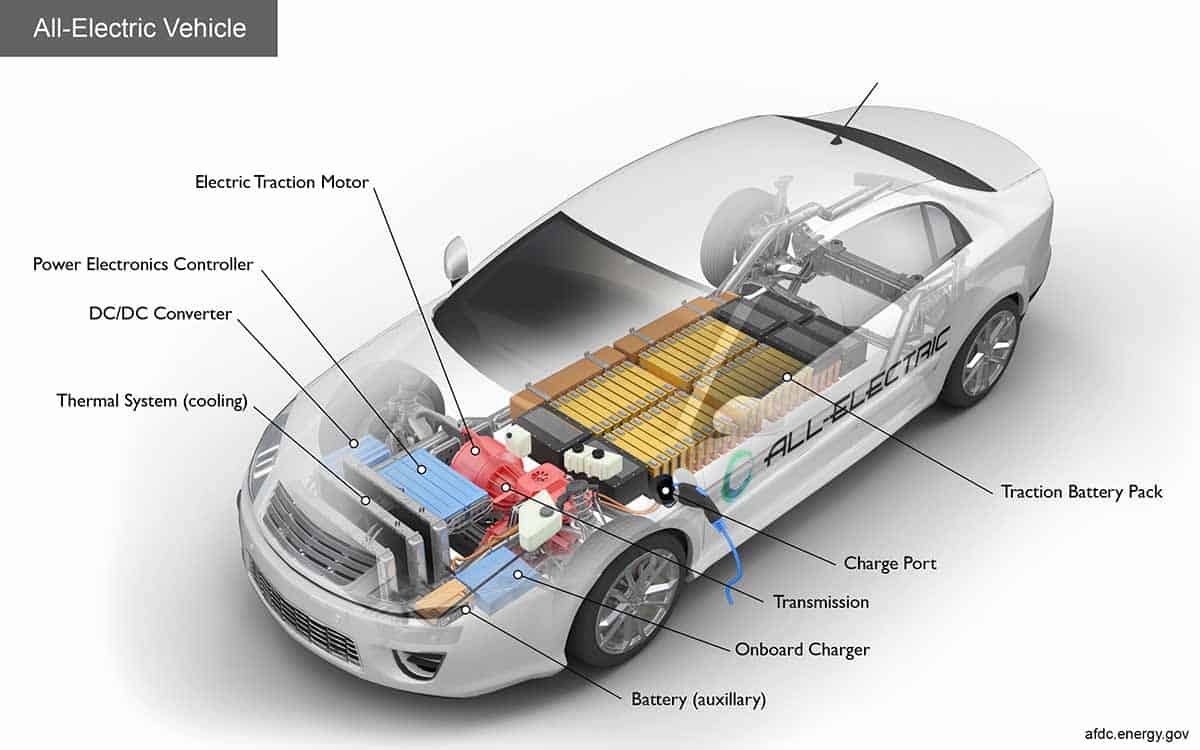

These cars have no internal combustion engine, no alternator to convert chemical energy into electrical energy, nor do they have a fuel-tank, or gearbox.

Components of Fully Electric Cars

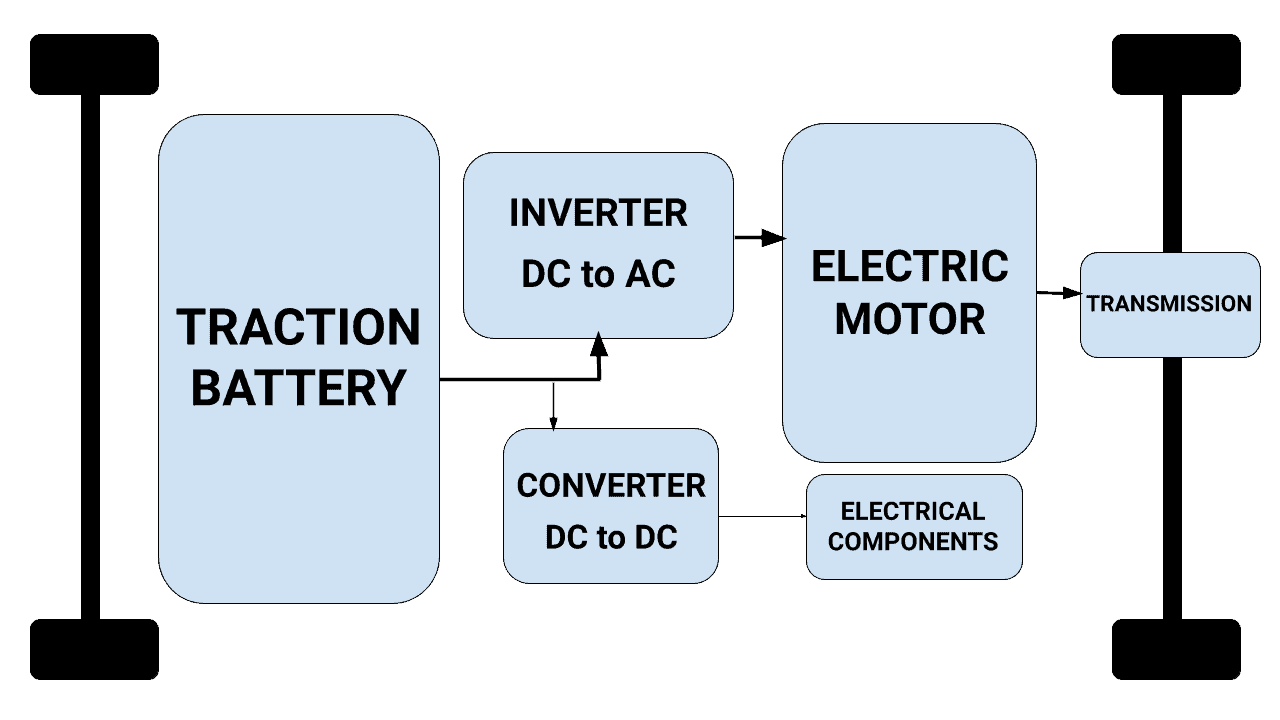

Electric cars have several key components that work together to deliver a smooth, efficient, and eco-friendly driving experience. This section will cover the main components: electric motor, traction battery, inverter, and DC converter.

Electric Motor

The electric motor is the primary source of power for an electric car. It uses electricity to generate torque, which is responsible for driving the wheels and propelling the vehicle forward. Electric motors are known for their instant torque delivery, resulting in quicker acceleration and smooth performance. They are also significantly quieter and more efficient than internal combustion engines.

Traction Battery

The traction battery is a critical component of electric cars as it stores the electricity needed to power the vehicle. These batteries are typically lithium-ion based and offer a high energy density, which contributes to the vehicle’s overall range. The battery capacity is often expressed in kilowatt-hours (kWh), and a higher capacity generally results in a longer driving range.

Inverter

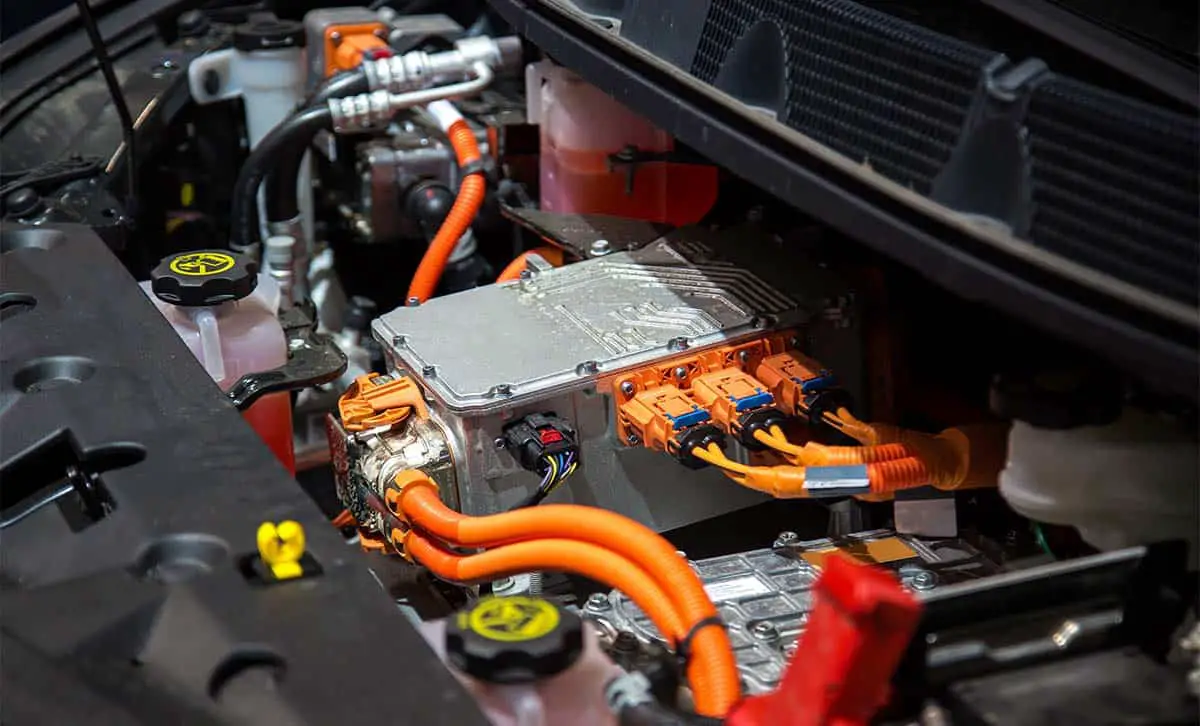

An inverter is responsible for converting the direct current (DC) delivered by the traction battery into alternating current (AC), which is needed to power the electric motor. Since electric motors require different levels of power depending on the driving conditions, the inverter must be able to adjust the frequency and voltage of the AC as needed. Inverters play a crucial role in optimizing the performance and efficiency of electric cars.

DC Converter

The DC converter is another essential component in an electric vehicle. It steps down the voltage coming from the traction battery to a level that can be used by other electrical components in the vehicle, such as lights, audio systems, and climate controls. By ensuring a steady and appropriate power supply, the DC converter contributes to the overall reliability and convenience of electric cars.

Charging and Battery Technology

All-electric cars use advanced battery technology for energy storage, providing power to the electric motors that propel these vehicles. These high capacity batteries cannot be charged the by the electric car itself and must be connected to an external power supply to be recharged.

The charging process involves three main factors: battery types, charging levels, and charging infrastructure.

Battery Types

Currently, lithium-ion batteries are the most popular choice for electric vehicles (EVs) due to their high energy density and long life cycle. They come in various capacities, measured in kilowatt-hours (kWh), which determines the vehicle’s range.

The average capacity of an electric car is 40 kWh, although they can be from 20 kWh to 100 kWh.

Charging Levels

There are three common levels of EV charging:

- Level 1: This is the slowest form of charging, using a standard 120-volt household outlet, providing about 2-6 miles of range per hour of charging.

- Level 2: These chargers use a 240-volt outlet, similar to those used for large appliances, and deliver 10-30 miles of range per hour, making it a suitable option for home and public use.

- Level 3: Also known as DC Fast Charging (DCFC) or Superchargers, these high-powered stations charge EVs at a rate of 60-250 miles of range per hour, ideal for long trips and commercial applications.

The time it takes to charge an electric car is also governed by how much current any given car is designed to take (measured in amperes or “amps”). Some cars are more limited than others in their amperage, and those with a lower limit, will take longer to charge than others with a higher limit using the same charger.

Between 16 and 32 amps is the typical range in which an electric car is designed to receive current when using a level 2 charging station.

Typically an electric car is designed for optimum charging anywhere from 16 to 32 amps when using a level 2 charging station.

Charging Infrastructure

Charging stations are a crucial part of the EV ecosystem, enabling drivers to recharge their vehicles outside their homes. There are different types of charging stations:

| Charging Station Type | Description |

|---|---|

| Home charging stations | Typically utilizing Level 1 or Level 2 chargers, these stations provide convenient and cost-effective charging for daily commutes. |

| Public charging stations | Often located in parking lots, malls, and commercial areas, these stations offer Level 2 and Level 3 chargers to cover short-to-medium range trips. |

| Fast charging stations | Strategically placed near highways and popular routes, these high-speed Level 3 chargers focus on long-distance travel and reducing charging time. |

As the number of electric vehicles on the road increases, so does the need for an extensive and accessible charging infrastructure, promoting the continuous expansion of charging stations worldwide.

Electric Vehicle Powertrains

Electric vehicle powertrains consist of several key components that work together to convert electrical energy into kinetic energy, providing the motion needed to drive the vehicle. Unlike traditional combustion engine vehicles, electric vehicles (EVs) rely solely on electric motors.

Electric motors play a critical role in an EV powertrain. They convert the electrical energy stored in the vehicle’s battery into kinetic energy, enabling the vehicle to move. The efficiency of an electric motor is generally higher than that of a gas engine.

Below is an overview of common EV powertrain components:

- Electric Motor: Converts electrical energy to kinetic energy, driving the wheels.

- Battery Pack: Stores electrical energy that powers the motor.

- Power Inverter: Changes direct current (DC) from the battery to alternating current (AC) for the motor.

- *Transmission: Transfers power from the motor to the wheels, optimizing speed and torque.

*An electric car has a transmission, but not in the sense that a traditional gas-powered car does.

As more people adopt EVs, advancements in powertrain design and components will continue to improve to meet the demands of the market.

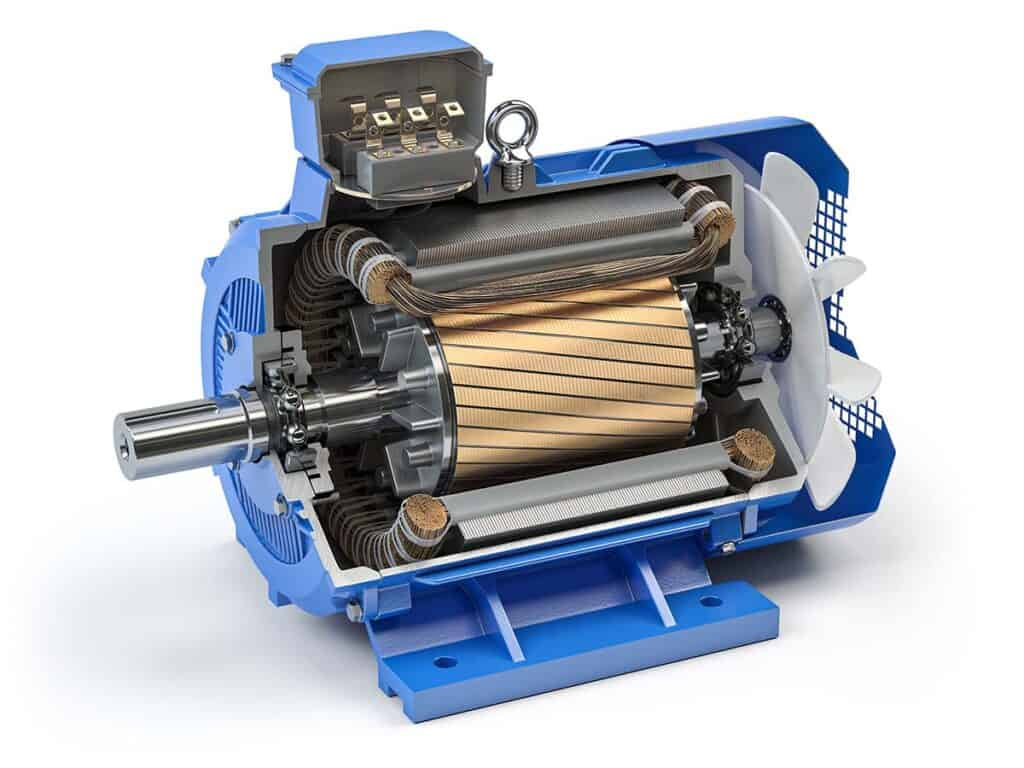

How Electric Motors Work

Electric motors are the driving force behind electric cars, converting electrical energy into mechanical energy. They rely on magnetism and magnetic fields to generate torque and power the vehicle.

Magnetism and Magnetic Fields

Magnetism is a fundamental force that occurs in certain materials such as iron, nickel, and cobalt. When these materials are arranged in a specific way, they create a magnetic field, which is an invisible area of space where the magnetic force is exerted. Electric motors use two types of magnets to create their magnetic fields: permanent magnets and electromagnets.

Permanent magnets have a fixed magnetic field, while electromagnets use electric currents to produce a magnetic field that can be varied in strength. Electric motors predominantly use electromagnets, which can be formed by running a direct current (DC) or alternating current (AC) through a coil of wire wrapped around a core made of ferromagnetic materials.

Generating Torque

Torque is the turning force that propels the wheels of an electric vehicle. Electric motors rely on the interaction between the magnetic field generated by the stationary electromagnets and the magnetic field created by the rotor’s electromagnets to produce torque.

When the alternating current (AC) or direct current (DC) flows through the motor’s windings, it creates a magnetic field that interacts with the rotor’s magnetic field. This interaction generates an electromagnetic force, which causes the rotor to rotate and produce torque. The higher the current, the more torque the electric motor generates.

Electric motors in electric cars have the advantage of delivering instant torque, resulting in better acceleration compared to conventional internal combustion vehicles. Furthermore, electric motors are more efficient and produce less noise and vibration, providing a smoother driving experience.

Types of Electric Vehicles

There are various types of electric vehicles available, each with their own unique features and advantages. In this section, we will focus on two main types of electric vehicles: Battery Electric Vehicles (BEVs) and Hybrid Electric Vehicles.

Battery Electric Vehicles (BEVs)

Battery Electric Vehicles, also known as all-electric vehicles or simply BEVs, are powered entirely by electricity stored in their onboard battery packs. These vehicles do not have an internal combustion engine and rely solely on electric motors for propulsion. Some key features of BEVs include:

- Zero tailpipe emissions, reducing air pollution and greenhouse gases

- Lower operating and maintenance costs compared to conventional vehicles

- Smooth and quiet operation due to the absence of an internal combustion engine

- Regenerative braking systems, which help increase the vehicle’s range by recovering energy during braking

BEVs can be charged at home using a standard electrical outlet or a dedicated charging station, as well as at public charging stations. Charging times vary depending on the type of charger and the capacity of the battery.

Hybrid Electric Vehicles (HEVs)

Hybrid Electric Vehicles, commonly referred to as hybrids, are a combination of an internal combustion engine and one or more electric motors. There are several subcategories of hybrid vehicles, including:

- Parallel hybrids, where the electric motor and internal combustion engine work together to power the vehicle

- Series hybrids, where the internal combustion engine generates electricity to recharge the battery and/or power the electric motor

- Plug-in hybrids, which can be charged from external sources and operate as BEVs for a limited range before the internal combustion engine takes over

Hybrid vehicles offer several advantages over conventional vehicles, such as improved fuel efficiency, reduced tailpipe emissions, and the flexibility to use either gasoline or electricity depending on driving conditions and availability of charging infrastructure.

Comparison to Internal Combustion Engine Vehicles

Electric cars have significantly different characteristics compared to internal combustion engine (ICE) vehicles. This section will explore the comparisons between the two types of vehicles in terms of performance, environment and emissions, as well as maintenance.

Performance

Electric cars offer smooth and instant torque delivery, which gives them very fast acceleration. The acceleration of an electric car is usually faster than that of a gas-powered car.

Due to the absence of a multi-gear transmission, electric vehicles have a single-speed transmission system that provides seamless power. This results in a more comfortable, quiet, and efficient ride.

The experience of driving an electric car is so quiet, in fact, that some models of all-electric cars have fake engine noises which help the driver to be more aware of when they are accelerating, as well as alerting pedestrians to their presence.

In contrast, ICE vehicles rely on the combustion of gasoline or diesel fuel to generate power. This process involves a more complex multi-gear transmission system, which can cause delays in power delivery and create more noise and vibrations during operations.

Environment and Emissions

One of the main differences between electric cars and ICE vehicles lies in their impact on the environment. Electric vehicles produce zero tailpipe emissions, thereby eliminating pollutants released directly into the environment from the vehicle’s use.

However, the emissions associated with electric vehicles depend on the sources of electricity used to charge their batteries. If the electricity is generated from clean renewable energy, the overall emissions are drastically lower when compared to conventional ICE vehicles.

ICE vehicles, on the other hand, emit pollutants such as carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter (PM) through their exhaust systems. These emissions contribute to air pollution and have negative effects on human health, as well as increasing greenhouse gas emissions that accelerate global warming and climate change.

Another important factor to take into account when evaluating an electric car’s environmental impact in comparison to an ICE car, is the need for lithium, nickel, and cobalt to make the battery. The mining carried out to extract these minerals for EV production is a source of greenhouse gas emissions.

However, the gasoline used to run ICE vehicles also produces emissions in all the phases of its production: when extracting the petroleum from the earth, during its refining process, and in its distribution to fuel stations.

Maintenance

When it comes to maintenance, electric cars generally require less attention. Due to their simpler design and absence of an internal combustion engine, there are fewer moving parts, reducing the potential for mechanical failures. Regular maintenance tasks for electric vehicles involve checking and replacing brake fluid, coolant, and tires.

An all-electric car certainly doesn’t require engine oil changes as its engine is not mechanical, completely lacking pistons or valves, so doesn’t risk seizing due to lack of lubrication.

Conversely, ICE vehicles require more frequent maintenance and replacement of various components, such as oil and filter changes, spark plug replacement, and timing belt inspection. Additionally, the combustion process can create carbon deposits that decrease engine efficiency and performance, necessitating further maintenance.

Conclusion

By delving into the components of an electric car, such as the battery, electric motor, and power electronics, we can understand how this type of vehicle differs from traditional gas-powered cars.

This knowledge can help you to make informed decisions about your transportation choices, from understanding the range and charging time of different electric car models to the potential cost savings over time.

I hope you found the article informative and that it answered your questions about how an electric car works. If you have any questions, please write them in the comments section below.

- Tesla Charger Installation Cost (Home Setups) - March 1, 2024

- Tesla Phone Key Disconnected (Troubleshooting Guide and Quick Fixes) - March 1, 2024

- Tesla FSD 12 (Explained) - March 1, 2024